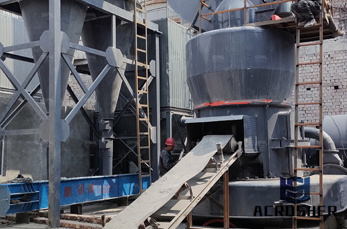

Hammer mills ANDRITZ

Highperformance hammer mills for optimum size reduction of raw material. Decades of experience and highly qualified product specialists make us a strong partner in the supply of hammer mills .

WhatsApp)

WhatsApp)

Highperformance hammer mills for optimum size reduction of raw material. Decades of experience and highly qualified product specialists make us a strong partner in the supply of hammer mills .

HAMMER MILL Highperformance grinding for many applications We are crushing it – no matter what it may be A COMPLETE SOLUTION The correct combination of hammer mill type, screens, hammers, speed, feeding system, and air flow through the hammer mill ensures the required grinding results and creates optimum conditions for

Optimizing hammer mill performance through screen selection and ... illustrating improved size reduction via optimization of hammer mill configuration, improved size ..... of balancing machine performance with product qual. ... Design of hammer mills for optimum performance Mircea Fenchea ... Fenchea M (1998) Dynamics and Balance of Rotors ...

In the brewing industry, a standard grist is required that has been proven to allow optimum application and absorption of enzymes into the mash stage of the process. This can only be achieved by the use of roller mills, often triple roller mills where product is ground twice to achieve the desired grist spectrum.

The performance of a hammer mill fabricated in Uganda was evaluated and the optimal performance conditions were determined. The evaluation was done with screen hole diameters (S) of,, and mm, hammer tip speeds (H) of,, m s1 and hammer thicknesses (T) of,, and mm for determination of energy consumption and final particle size (GMD) using a modified ...

the right type of mill, how to operate your mill efficiently, and how to maintain your mill. There are numerous types of grinding mills. This article focuses on two widely used types: the hammer mill and the jet mill. Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from

Lower maintenance costs are an added benefit of the Hammermill since each hammer can be turned four times, extending the mill''s productivity. Optimal hammer design and placement will provide maximum contact with the feed ingredient. The durable design of the drive bearings and shaft also help to keep maintenance costs down.

Is a hammer or roller mill better for pig feed structure? ... The authors noted advantages and disadvantages to be considered when choosing the optimal mill. "Hammer mills have greater capacity of grinding and it is easier to switch from one grain to another by changing the sieve. ... resulting from the use of different mill types, on growth ...

Kosse, Vladis Mathew, Joseph (2001) Design of hammer mills for optimum performance. Journal of Mechanical Engineering Science (Proceedings of the Institution .

Existing design approaches have proved to be incapable of explaining this phenomenon. This paper presents a new approach to hammer mill design and enables the prevention of increased vibrations and uneven wear and, finally, provides better performance of hammer mills

Hammer mill screens Screen design for hammer mills There are many ways to reduce the particle size of cereal grains for feed ingredients. One of the most common ways is to use a hammer mill. The open area in a hammer mill screen determines the particle size and grinding effi ciency. The screen must be designed to maintain its integrity

DESIGN AND EVALUATE OF A SMALL HAMMER MILL. MOHAMED, T. H., H. A. ... a very little knowledge about optimum processing ... Design and Performance of a .

hammer pin. Excessive wear of the hammer holes or grooving of the pins generally indicated an inconsistent feed (surges that cause the hammers to rock on the pins) or the need for a heavier hammer pattern. This is especially true on machines with lower tip speeds such as 38" diameter mills with 1800 RPM motors. As hammer manufacturers improve the

There are many variations to the windmill design used by William Kamkwamba and refined throughout this section. However, there are some variations that are commonly used and have a negative impact on performance. One of these examples is using wood as the material to create blades.

Hammer and Screens • Hammers are single hole and cut from alloy steel with a wear resistant tungsten carbide matrix. Pins are case hardened 5660 rc, stress relieved and straightened. • All hammer sets are balanced and matched for optimum performance and wear.

Optimal hammer design and placement will provide maximum contact with the feed ingredient. Hammer mills in which the rotor speed is approximately 1,800 rpm, should be using hammers which are around 25cm (~ 10 inches) long, (~ inches) wide, and ( inches) thick.

The correct combination of hammer mill type, screens, hammers, speed, feeding system, and air suction through the hammer mill ensures the required grinding results and creates optimum conditions for subsequent processes, such as mixing, pelleting, and extrusion. Thus. the grinding process is not merely a question of the hammer mill alone, but

Download Citation on ResearchGate | Design of hammer mills for optimum performance | In hammer mills, the grinding process consists of hitting the material by hammers, articulated on a rotor. It ...

The design and construction of hammer mill becomes imperative as that will go a long way in getting processed cereals grains easily within developing nations. Hammer mill (cereal miller) is a device consisting of a rotating head with a free swinging hammer or ... hammer mills discharge opening. Optimal screen size is determined by the desired ...

Development and Testing of a Hammer Mill A. Nasir Department of Mechanical Engineering, Federal University of Technology Minna, Niger State, Nigeria Abstract The hammer mill was designed and constructed from locally available materials for grinding grain particles such as maize, millet, guinea corn and other coarse

Hammermill. ® Paper for Life. ® Hammermill paper is scientifically designed and rigorously tested to perform at the highest level everytime. For over 100 years, we have been dedicated to helping people capture ideas, share thoughts, and show their work at its best at work, at home, and in school.

Optimizing hammer mill performance through screen selection hammer design Research Article future science group 87 moisture increased. Moisture content in straw had less effect on grinding energy, although the same pattern was observed. Operating speed, moisture content and

DESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE HAMMER MILL AJAKA and ADESINA A. Department of Mining Engineering School of Engineering and Engineering Technology The Federal University of Technology, Akure, Nigeria ABSTRACT: The laboratory size hammer mill was fabricated from locally available materials

Uncomplicated, simple to operate Hammer Mills retaining high performance and the flexibility to answer your needs. ... With the ability to reconfigure your machine by changing selected parts quickly and easily and our wide range of screen design, you can seamlessly adapt to changing demands and future application needs. DASO6 Hammer Mill.

WhatsApp)

WhatsApp)