Magnetic Separation Process YouTube

May 27, 2014· Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is ...

WhatsApp)

WhatsApp)

May 27, 2014· Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force. This separation technique can be useful in mining iron as it is ...

The power of progress and technical tradition can be felt in each and every one of our STEINERT solutions for magnetic and sensorbased sorting and separation. We offer the latest in technologies available to the mining and mineral processing industries, including our multisensor ore sorting solutions.

In this study, enrichment methods for coal fly ash (CFA) from Omsk thermal power station No. 4 (TPS4) were investigated. The magnetite and unburned carbon concentrates were obtained by magnetic separation and flotation methods. The wet magnetic separation used in the study increased the magnetite content in the magnetic fraction from to wt % compared to dry magnetic separation ...

This article presents a summary assessment of different technologies and their performance in the beneficiation process of high ash coals with particular reference to Indian thermal coals. The literature on sorting, air jigs, magnetic separation, airdense medium fluidized bed separation, and electrostatic separation is summarized and discussed.

High moisture levels and a metal content to which, predominantly, other material adheres demands a separation technology specially designed for the purpose. As an alternative, dry procedures are used for the ash removal in which metal separation in the fine grain range can generally be .

Dry magnetic separation has also been used to achieve coal cleaning based on the fact that clean coal is a weakly diamagnetic material and some of the minerals associated with coal (particularly ...

Electrostatic Separation of Dry Granular PlantBased Food Materials. Kyle Flynn, Abhishek Gupta, Frank Hrach . Abstract Review of the relevant literature indicates that significant research has been undertaken to apply electrostatically separation techniques to dry granular plantbased food (, organic) materials.

Magnetic separation followed by Mozley Table on Nonmagnetic Products Fly ash contains iron compounds typically of hematite, and the use of fly ash in ceramic industry depends on its iron content, it must be lower than 2 %. Therefore, magnetic separation was carried out for the removal of magnetic particles from fly ash.

A combination of semicoking followed by a permanent roll magnetic separator (PERMROLL) has been used for the upgrading of a Turkish lowrank lignitic coal. The lignite samples were subjected to a low temperature carbonization process at 600°C and

Jun 16, 2013· ApplicationsThe magnetic drum separator is ideal for separating iron particles fromgranules powders It is widely used in the following industries:•Glass•Ceramic•Chemical•Fertilizer•Plastic•Food industry•Iron and steel slag treatment•Reduced pyrite ash separation•Calcined ilmenite productionMetal powder production 13.

To separate ash fractions with such particle size, it is possible to use pneumatic separation, magnetic separation and triboelectrostatic separation. The use of pneumatic separation for extraction of ash fraction out of coal has been studied rather well [ 9, 10 ] and has not been considered in this study.

Performing a dry magnetic separation on this system, whose constituents have known magnetic properties, will provide us with data we can compare directly to the water slurry results. These tests should be supplemented with more extensive tests on coal .

Dry low intensity magnetic separation dry drum separators have been developed mainly for dry separation of ferromagnetic ores with particle sizes finer than 20 mm. In addition to this conventional application, the dry drum separator has found a wide range .

Permanent Magnetic Separators The science of magnetic separation has experienced extraordinary technological advancements over the past decade. As a consequence, new applications and design concepts in magnetic separation have evolved. This has resulted in a wide variety of highly effective and efficient magnetic separator designs. In the past, a process engineer faced with a magnetic ...

LIMS dry drum. ''s LIMS dry drum low intensity magnetic separators consist of a stationary magnetic yoke with a number of permanent magnets placed inside a rotating drum of nonmagnetic .

uses two very strong forces to separate small dry particles and has applied it to separation of fly ash. These forces — aerodynamic and magnetic — dominate other surface and mass forces allowing for efficient separation of fly ash into value added products including magnetite,

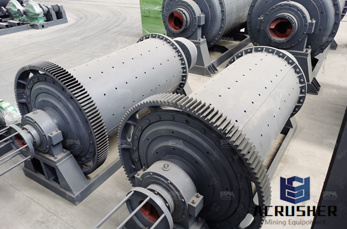

Separation equipment of ferro oxides from fly ash is composed of the jaw crusher, ball mill, classifier, magnetic separator, flotation machine, thickener, dryers and other major components for prepared with feeder, elevator, conveyor can be composed of a complete sand separation iron equipment.

Reduction of Ash and Sulfur Contents of LowRankTurkish Semicoked Lignite by High Intensity Dry Magnetic Separation. G. ATESOK Istanbul Technical University Mining Faculty, Mineral and Coal Processing Section, Maslak, Istanbul, 80626, Turkey .

Three Disc Dry Magnetic Separator applicable to dry separation of titanium, rare earth ore, tungstentin ore, chromite, niobiumtantalum ore, Limonite, Zircon, gold red, solitary, feldspar, quartz and other magnetic differences in a variety of metallic minerals or nonmetallic materials of the iron remover, but also magnetic and nonmagnetic minerals separation purification.

Aug 25, 2016· Dry fly ash material was fed by a vibration into the magnetic field, and ferromagnetic particles were drawn to and pulled Electrostatic Separation Technology, The Association of Benefits of .

When you need magnetic separation the Reading range of magnetic separators has a wide range of proven, cost effective products. Including wet high intensity, induced roll, rare earth roll, rare earth drum, low intensity and medium intensity magnetic separators the Reading range has a magnetic solution to fit your particular processing requirements.

Eriez DF High Speed Drum Magnets. Dry Low Intensity Magnetic Separators (DLIMS) for automatic continuous concentration of magnetic ores, removal of magnetite from fly ash, purification of ground slag, foundry sand, cement and minerals.

magnetic separation step three times in order to assure a complete separation. Typical analyses of the resultant separated ash fractions are shown on Table I . PROPERTIES OF THE MAGNETIC FRACTION OF FLY ASH The magnetic ash fraction is dense and consists of very small parti cles.

Find here dry magnetic separator for ore or professional Dry Electromagnetic Separator technology, equipment and machine from POWTECH. Our company is one of the leading China manufacturers and providers specialized in the production of dry magnetic separator for ore machinery. Welcome to .

WhatsApp)

WhatsApp)