raw materials needed for cement grinding plant

raw materials needed for cement grinding plant. Rawmill Wikipedia However, cement raw materials are for the most ... and new wet process plant is now rarely installed.

WhatsApp)

WhatsApp)

raw materials needed for cement grinding plant. Rawmill Wikipedia However, cement raw materials are for the most ... and new wet process plant is now rarely installed.

three grinding stages, but the development of more energyefficient vertical roller mills (VRMs) led to their replacement. Initially, this focused on grinding coal and the cement raw materials, with the adoption of vertical roller mills for cement product grinding – with its finer grinding requirements – coming more recently, in the late ...

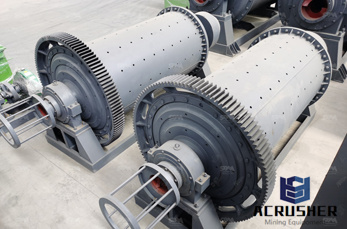

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

The trusted product source — and expert resource — for cement producers worldwide. More than 80 years ago, we pioneered the development of chemical additives to make grinding cement more efficient. Since then, we have led the industry in making new compounds to improve cement grindability and .

Grinding Mill Machine in Cement Production. Zenith provides both large scale and small scale cement production plants for sale, which are available with crusher plant, cement grinding mill, ball mill, vertical roller mill, rotary kiln etc.

Mar 03, 2015· Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in ...

budget required for cement grinding plant trigocoin home budget required for cement grinding plant Vietnam is an important Get More Info budget required for cement grinding plant Ice plant requirements Space power and refrigeration requirements are discussed and the main types of icemaker are described Methods of handling.

Respirators: Because What You Can''t See Can Hurt You. ... In the real world, using a respirator in a precast concrete plant can sometimes be viewed as a nuisance. Either it''s too hot to wear, it''s difficult to talk through or it just gets in the way. ... due to concrete cutting, grinding, coring, stoning, cement mixing and sweeping, or ...

The setting up of greenfield cement projects means starting from scratch at a new location / site with the land and infrastructure as available. The greenfield plant can be set up as integrated plant or with split location where clinker can be manufactured at one location and cement grinding and/ or packing can be at another location.

Cement Plant Machinery. OVERVIEW. ... with various reputed and proven technology providers overseas WIL offers you a single source solution for everything needed to set up a new modern, power and fuel efficient cement plant and clinker grinding units. ... Expansion and modernization/retrofit of existing cement plant and clinker grinding units ...

what are the plants machinery required for cement,, budget required for cement grinding plant, what are the plants machinery required for cement, 24/7 online; raw materials needed for cement grinding plant. Raw Materials Needed For Cement Grinding Plant: Can I Make My Manufacturing process . All about Cement

AGICO is a leading cement equipment manufacturer in China, supporting highquality cement kilns, grinding mills, crushing mills, dust collectors, conveying equipment and other machines that needed in the cement plant. We offer the customization, installation, commissioning and operation training service of our cement equipment.

Rent a Concrete Grinder 10" from your local Home Depot. Get more information about rental pricing, product details, photos and rental locations here.

Energy consumption assessment in a cement production plant is studied in this paper and a guideline for reducing energy consumption is provided according to a national standardISIRI 7873. Based on energy assessment, several energy saving actions were implemented and valuated.

When it comes to achieving the best energy consumption, what are the key factors a cement producer needs to address? In this article, extracted from the newly published Cement Plant Environmental Handbook (Second Edition), Lawrie Evans presents a masterclass in understanding and optimising cement plant energy consumption.

Cement plant machinery equipments used in cement plants are compact, powerful and reasonably priced that meet all applications, to give trouble free and competent performance. Unit has all the skills to commence all aspects of cement plant construction. Ashoka cement plants India are .

raw materials needed for cement grinding plant. ... cement making plant is used in cement raw material crushing plant. you need to choose suitable cement grinding ... raw materials for grinding cement ... Lafarge The raw materials needed to produce cement (calcium carbonate, silica, ... Raw material and cement grinding ...

Mar 02, 2017· From the pioneer and pacemaker in grinding. The intelligent concept of LOESCHE''s CCG Plant enhances your flexibility during operation. You .

Rawmixes frequently contain minerals of contrasting hardness, such as calcite and quartz. Simultaneous grinding of these in a rawmill is inefficient, because the grinding energy is preferentially used in grinding the softer material. This results in a large amount of excessively fine soft material, which "cushions" the grinding of the harder ...

2010 survey, Essroc Cement Co.''s Essexville grinding plant ceased operations and Essroc''s grindingonly facility in Nazareth, PA was combined with their clinkerproducing plant – bringing the number of grindingonly plants to seven. cement manufacturing is primarily a fossil fuel fired industry with % of all plants using coal ...

More than 250,000 people work in concrete manufacturing. Over 10 percent of those workers 28,000 experienced a jobrelated injury or illness and 42 died in just one year. Potential hazards for workers in concrete manufacturing: Hazard: Exposure to cement dust can irritate eyes, nose, throat and ...

The Ramla cement plant (see Fig. 1 for an aerial photo of the plant) has been in operation for 46 years. The original process at the Ramla cement plant to produce cement from limestone, which is the base material of cement, was a socalled wet line process. The .

Mortar testing requirements and controlling contractor responsibilities under the Steel Erection Standard. (December 27, 2002). Fall protection requirements for employees working from a "work bridge" in concrete construction work. (December 9, 2002). Steel erection concrete testing requirements and number of samples required to be taken ...

Cement Grinding... are one of five required... cost of the cement plant will depend on how cheap . Cement Plant Equipments, Cement Machinery . Cement Machinery Manufacturers: Cement Plant Equipment ... of its cement plant .

WhatsApp)

WhatsApp)