silico manganese slag in concrete BINQ Mining

Silico Manganese in Cement Production. At the end of the original processing of Silico Manganese ore to remove as much metallic manganese as possible, one is left with what is referred to as a slag .

WhatsApp)

WhatsApp)

Silico Manganese in Cement Production. At the end of the original processing of Silico Manganese ore to remove as much metallic manganese as possible, one is left with what is referred to as a slag .

Manganese processing | Manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such ...

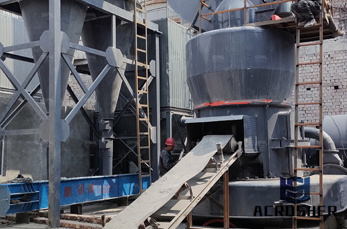

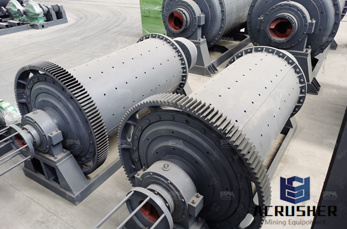

prossing of silico manganese slag If silico manganese slag is used less fuel is required to Manganese processing equipment. There is a manganese production line provided by Gulin in Mexico. Silico Manganese Manufacturing Process and its .

The calculation of equilibrium phases in the reduction process of manganese ores using FACTSage correctly reflects the trends in the production of manganese alloys. The temperature at which the manganese oxide concentration in the slag was reduced below 10 wt pct can be assigned to the top of the coke bed in the silicomanganese furnace.

Silicomanganese with 10–26 percent Si (the remainder is Mn, Fe, and impurities) is obtained from manganese ore, manganese slag, and quartzite and is used as a deoxidizer and alloying additive in the smelting of steel, as well as in the smelting of ferromanganese with reduced carbon content by the silicothermic process. Silicomanganese with 28 ...

Jun 09, 2018· Silico Manganese Silicomanganese (SiMn) is a metallic ferro alloy which is being used to add both silicon (Si) and manganese (Mn) as ladle addition during steelmaking. Because of its lower carbon (C) content, it is a preferred ladle addition material during making of low carbon steels.

Silico Manganese Slag Carbon Enterprises Silico manganese slag is precalcined. Approximately 65% of the fuel used in cement production is used in the calcination phase, so if .

silico manganese slag plant in germany. Silico Manganese Slag Carbon Enterprises. At the end of the original processing of Silico Manganese ore to remove as much metallic manganese as possible, one is left with what is referred to as a slag, Get Price. Silicon Manganese, Silicon Manganese Suppliers and .

is a loss of about 15% of manganese as slag. The remaining 85% of manganese alloy is further divided and used into crude steel (90%) and others (10%). Manganese alloy used for steel making constitute of the following three grades: high carbon ferromanganese (HCFeMn/FeMn), refined grades with medium carbon (MC) and low carbon (LC) and silico ...

Silico manganese HIRA Godawari Power Ispat Limited. Silico Manganese is an essential component as an ingredient in the process of manufacturing various grades of steels. Silico Manganese, High Carbon Ferro Manganese, Medium Carbon Ferro Manganese, is covered under routine production planning. Get Price

Silico manganese is used as a deoxidant, sulfide former and alloying element in the steel industry, or in the production of other manganese alloys. In the case of stainless steel, it is also used to substitute expensive nickel in some austenitic grades. It is produced from manganeserich slag a byproduct from ferro manganese production.

Dec 12, 2017· The manufacturing process of silico manganese undergoes preheating, pre reduction and coke bed zone. A furnace is used to reduce the ferro manganese slag and the manganese ore placed at the top of the coke bed. However, it is seen that behavior of the charged materials depends upon the heating and its intensity of reaction with carbon.

Ferro Manganese Silico Manganese Process Plants. Silico manganese quarry mining process lenins. Silico Manganese, ferro silicon used in chrome beneficiation plant mine quarry Ferro Process Of Mining Silicon. what is the process of mining Check price process for making silico manganese shibangchina. Obrolan Dengan Penjualan.

Silico Manganese Exporters in India. We are engaged in offering High Carbon Silico Manganese (60/14) to our clients. Our Ferro Silico Manganese contains high amount of both silico and manganese owing to which it find applications in various industrial processes especially in the manufacturing of steel and iron as an oxidizing agent.

metallothermic reduction of the manganese waste slag. The intention was to produce both a modified slag and a silicomanganese alloy as products, leaving zero waste. Minteks Pyrosim thermodynamic simulation tool6 was used to calculate the feed recipes and both experimental test work approaches were conducted using a 40 kW

Ore Processing Equipment Silico Manganese Slag Jig Machine, Find Complete Details about Ore Processing Equipment Silico Manganese Slag Jig Machine,Jig Machine,Slag Jig Machine,Silico Manganese Slag Jig Machine from Supplier or ManufacturerJiangxi Victor International Mining Equipment Co., Ltd.

Manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such

Concrete made with Mn slag as supplementary cementitious materials (SCMs) exhibits very low strength loss and weight loss in the synthetic seawater corrosion and freezingthawing cycle tests. The research provides useful reference for knowing about Mn slag and for applying Mn slag to improve the durability of concrete.

At the end of the original processing of Silico Manganese ore to remove as much metallic manganese as possible, one is left with what is referred to as a slag, comprising granules of silico manganese denuded ore. The slag is then further processed by crushing and washing to remove as much of the remaining metal as possible until further ...

Jun 09, 2018· Production of SilicoManganese in a Submerged Arc Furnace. Silicomanganese (SiMn) is an alloy used for adding both silicon (Si) and manganese (Mn) to liquid steel during steelmaking at low carbon (C) content.

Request PDF on ResearchGate | Recycling of Silicomanganese Slag as Pozzolanic Material in Portland Cements: Basic and Engineering Properties | Correct use of SiMn slags requires a detailed ...

silicon manganese slag for reclaiming land dewittplace. silico manganese slag used as abrasive . silico manganese slag used as abrasive | SBM Crusher Solutions. Get Price And Support Online; Optimisation of SiMn Production at Transalloys. Metallics in the slag are reclaimed in a jigging plant, . slag and reductants.

PDF | The main source of Mn in raw materials for SiMn production is Mnore and Mnrich slag from the high carbon FeMn production. The amount of slag per tonne of SiMn metal is mainly determined by ...

Silico Manganese Manufacturing Process and its different ... Dec 12, 2017· The production process of silico manganese goes through stages such as smelting, and slag formationandreduction. Here is the detailed discussion on the stages: Stage 1: It revolves round heating and pre reduction in the solid state at 1373 K and 1473 K.

WhatsApp)

WhatsApp)