Global cement production top countries 2018 | Statista

This statistic shows the worldwide cement production, by major producing countries, from 2012 to 2018. In 2018, cement production in the United States amounted to some million metric tons ...

WhatsApp)

WhatsApp)

This statistic shows the worldwide cement production, by major producing countries, from 2012 to 2018. In 2018, cement production in the United States amounted to some million metric tons ...

Oct 10, 2019· Further the equipment can be adapted for the production of standard concrete walls and floors as well. Pallets Carousel Line, Pallets dimension/max. element size: x m. Complete Concrete Mixing plant with cement silos, aggregates silos, conveyor belts, bucket elevator etc. .

Usually, a lower FM results in more paste, making concrete easier to finish. For the high cement contents used in the production of highstrength concrete, coarse sand with an FM around produces concrete with the best workability and highest compressive strength.

The casing cement top must isolate any hydrocarbon zones. Some wells require multiple intermediate strings. Some intermediate strings may also be production strings if a liner is run beneath them. Production casing. Production casing is used to isolate production zones and contain formation pressures in the event of a tubing leak.

The fineness and particle size distribution of Portland cement. The final step in the production of cement is to grind the clinker pellets (and added gypsum) into a fine powder. The resulting individual cement particles have a variety of angular shapes, and a wide range of sizes (see Figure 37 below).

Specification for the Manufacture of Concrete Poles . This material is made available on the basis that it may be necessary for a Registered Professional Engineer of Queensland (RPEQ) to undertake or oversee the engineering services to meet statutory obligations.

bulk density of li ne aggregate Aggregates in Concrete University of Washington Professor Kamran M. Nemati Winter Quarter 2015 5 Concrete Technology Aggregates for Concrete Concrete Technology 9 Natural mineral aggregates,, sand and gravel have a bulk density of 95 to 105 lbs/ft3 (1520 1680 kg/m3) and produce Normal Weight concrete (NWC).

Oct 16, 2017· Casing is the major structural component of a well. It is a tubular steel product used to line the wellbore (maintain borehole stability), prevent contamination of water sands, isolate water from producing formations, and control well pressures during drilling, production, and workover operations.

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

The cement industry is a bellwether for the economy – it is tied to construction, infrastructure, energy and many other sectors. The Portland Cement Association''s award winning team of economists provides guidance and analysis on the manufacturing and use of cement across industrial sectors through graphs, reports and thought leadership.

Coal crusher used in cement making industry YouTube. Sep 07, 2016 · cement grinding plant and sand making coal crusher,jaw crusher,Impact Coal Gangue Crusher,Cement Production Line,Ring Hammer Crusher Crushing How to select the most suitable coal gangue crusher. High Quality Mini Stone Crusher Process Coal Gangue At ...

Concrete: Scientific Principles. The production of portland cement begins with the quarrying of lizenithne, CaCO3. ... Aggregates come in various shapes, sizes, and materials ranging from fine particles of sand ... crushed recycled concrete, used for normal concrete projects.

In the manufacture of Portland cement, clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter, produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

Oct 27, 2017· Cement is mostly used for the production of concrete: in the United States, some 71 percent of cement sales went to producers of readymixed concrete and .

Precast concrete façade panels were used mainly in apartment buildings, less so in individual houses. This can also be seen in architectural publications from the period 1945 to 1975. Among the approximately 160 cases of houses for which the materials used were described, about 20 of them continued precast concrete façade elements.

Concrete Technology Concrete is a construction material composed of cement, fine aggregates (sand) and coarse aggregates mixed with water which hardens with time. Portland cement is the commonly used type of cement for production of concrete. Concrete technology deals with study of properties of concrete and its practical applications. In a building construction, concrete is used for the ...

Manufacturing the cement kiln. Most Portland cement is made in a rotary kiln. Basically, this is a long cylinder rotating about its axis once every minute or two. The axis is inclined at a slight angle, the end with the burner being lower.

Drilling Production It takes about six weeks to drill, hydraulically fracture and complete a typical well, but the work begins long before a well is ever "spud," and a producing well will continue working for North Dakota much longer thereafter.

Chapter 8 Design of Concrete Mixes Total 60 Chapter 5 Concrete Mix Design ... from different works and to normal variations in production from any one works over a period of time. ... type and maximum size of the aggregate to give a concrete of the specified slump or Vebe time.

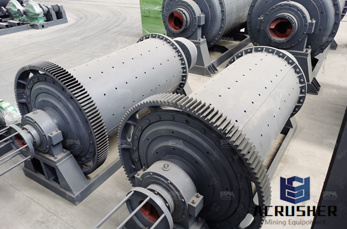

Cement mill . A cement mill is the equipment used to grind the hard, nodular clinker from the cement kiln into .... However, the narrowness of the particle size distribution of the cement is .

Sometimes, customers require early concrete strength of over 5 MPa in fourteen hours, even if the only production line of normal cement is available in the cement plant, or if the limited number of batch plants for normal cement in the construction sites is operated for the massive construction projects.

If neat cement grout is used to seal a bore hole it should be composed of a thorough mixture of Portland cement and clean water at a rate of one bag (94 lbs.) of cement to 5 to 6 gallons of water so that it can be pumped or puddled into the annular space to seal it.

Cement and water combine chemically to bond the sand and coarse aggregate together. Ground granulated blast furnace slag and flyash may also be used as cementing materials, but always in combination with cement. The volume of water added to a certain volume of cement determines, to a large extent, how strong the hardened concrete will be. Most

Crushers may be used to reduce the size, or change the form, of waste ... It was only after explosives... Read More. How Cement Is Made The Portland Cement Association. ... Pozzolana Cement Production Line Gypsum Block Production Line. Pozzolana cement production line process, most of the raw material to be broken, ... raw material, the ...

WhatsApp)

WhatsApp)