Basic End Mills Technical Information | MSC Industrial ...

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used .

WhatsApp)

WhatsApp)

Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing. A ball end mill is constructed of a round cutting edge and used .

Aug 10, 2020· Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder. Ceramic material, crystalline compounds, and even some metals can be ground up using a ball mill.

Aug 19, 2018· You can be easily identified as ball cutters as their end is hemispherical in shape. Ball cutters are used to decrease the stress concentration and are also known as ball end mills. Whenever there is a need of cutting threedimensional shapes then, there is a use of ball cutters to perfectly cut those threedimensional shapes. 6. Involute Gear ...

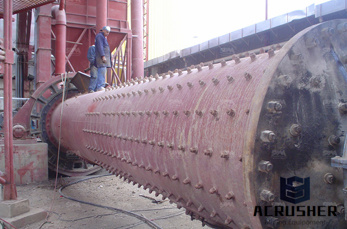

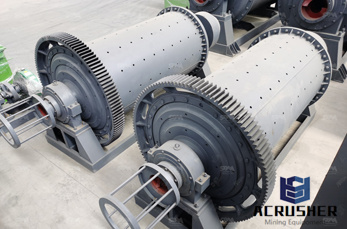

Energy Saving Ball Mill * Product Introduction A high efficiency and energy saving ball mill with rolling bearing * Capacity Up to 160t/h * Product Improvement Cylindrical energy saving grid ball mill is lined grooved ring plate which increases th...

Download Ball mill stock photos. Affordable and search from millions of royalty free images, photos and vectors.

This is my homemade gold ore ball mill to process lode claim material. Uses steel balls or i have a large round wheel made of steel to also crush. This could...

Buy Used Ball Mills. 51 Items Available Filter By Manufacturer. Sorty By 2 Units ALLIS CHALMERS 11''6" x 19''6" Ball Mills, 1250 HP. Inventory ID: 6CNG01. 2 Units ALLIS CHALMERS 11''6" x 19''6" Ball Mills, 1250 HP. Manufacturer: ALLIS MINERAL SYSTEMS ...

Browse 667 ball mill stock photos and images available, or search for sag mill or mining to find more great stock photos and pictures. Explore {{}} by color family {{familyColorButtonText()}}

Ball mills for superfine calcium carbonate. Ball mill classifier systems have been improved over time and are now capable of achieving much finer products. In the past, a particle size with a D97 of 10 microns was only possible. Now particle sizes down to a D97 of less than microns can be achieved, with a D50 in the range of microns.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Ball nose spiral end mills are used for smooth contouring and fine detail passes with a CNC router and often for complex shapes like 3D carvings. The rounded ends produce smooth curves that would be impossible to achieve with flat end bits.

Lloyds''s book is the most complete and practical resource I know for information on ball milling theory and for plans to actually build your own ball mill. Here''s a shot of a nice, doublebarrel mill I built based on his principles. Homemade DoubleBarrel Ball Mill Ball milling replaces potentially unsafe hand grinding of chemicals and ...

Pharmaceutical uses of Ball Mill. 1. The small and average capacity ball mills are used for the final grinding of drugs or for grinding suspensions. 2. The maximum capacity ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals.

Sep 11, 2016· This is my homemade gold ore ball mill to process lode claim material. Uses steel balls or i have a large round wheel made of steel to also crush. This could...

How to Make a Ball Mill: 12 Steps (with Pictures) Edit Article How to Make a Ball Mill Two Parts: Making the Ball Mill Using the Ball Mill Community QA Ball mills are a special instrument used to break up hard solids into a fine powder They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance into powder...

Ball Mills Pebble Mills – Basically a horizontal tube with balls or stone grinding media, that grinds the material as the tube rotates. Can be batch or continuous, wet or dry grinding. Colloid mills – these grind solids in slurry. Kady Mills – special type of high energy dispersion mill used to grind particles in slurry.

Picture Of Ball Mill With Uses. Picture Of Ball Mill With Uses; Ball mill Wikipedia. A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

6mm HRC45 Ball Nose Carbide End Mill Shank 2 Flutes Milling Cutter Drill Bits. Features: * brand new and high quality * Made of high quality material, durable and practical to use * Shockproof design, high surface finish and long tool life * Optimize the temperature and requirements of challenging materials such as superalloys

Jun 26, 2017· Ball Nose Milling Without a Tilt Angle. Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1).

Used US Stoneware Ball Mill. Used Stoneware Ceramic Ball Mill, 52 Gallon. Approximate 33" diameter x 28" long, dished ends. Inlet outlet with cover. Driven by a 3hp, 3/60/208230/460 volt, 1725 rpm motor, with Stearns brake and a gear reducer to 1. Mounted on carbon steel legs with a discharge housing. Serial# AX98101. VIEW ITEM

Rod mills operate at lower speed than ball mills since the rods are rolled and not cascaded. For an equivalent grind, a rod mill uses less steel than a ball mill because of the lower speed and better contact between the media and ore. The rod charge must be maintained in good working condition, and broken and worn rods must be removed.

The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder. Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill. These mills are also designated as .

Silicon Carbide Balls are very highcost grinding media that are used for milling same materials (silicon carbide ball to mill silicon carbide materials) to avoid contamination. They are only available in 5mm,10mm, 15mm and 20mm sizes. They are a special order item.

Up to10%cash back· The mill mark was used by several members of the Mülle, AdditionalRightsClearanceInfoNotAvailable Cylindrical body on three clawandballfeet. Three surrounding cartouches with depictions of landscapes between acanthus leaves.

WhatsApp)

WhatsApp)