International Cement Review News, Events Training

the home of International Cement Review, the world''s most requested magazine in the global cement industry. Leaders in News, Conferences, Training and Reports

WhatsApp)

WhatsApp)

the home of International Cement Review, the world''s most requested magazine in the global cement industry. Leaders in News, Conferences, Training and Reports

The aim of this Document is to provide background information on the cement industry and cement manufacturing technology, and to determine "best available techniques" for the installations for production of cement. In preparation of this Document the cement .

Dayton Superior engineers have the industry''s deepest expertise in every area of concrete construction, including all foundation types, commercial buildings, pre .

The ultrigh performance concrete RabatSalé airport, Morocco AEThER®, A NEw gENERATION CEmENT Aether® is a revolutionary cement reducing CO 2 emissions by 25 % to 30 %. Industrial trials successfully performed at the end of 2012 confirmed that Aether® cement achieves performance equivalent to that of our conventional cement.

The Occupational Outlook Handbook is the government''s premier source of career guidance featuring hundreds of occupations—such as carpenters, teachers, and veterinarians. Revised annually, the latest version contains employment projections for the 201828 decade.

A Review On Environmental and Health Impacts Of Cement Manufacturing Emissions Shraddha Mishra, Dr. Nehal Anwar Siddiqui Health, Safety Environment, University of Petroleum Energy Studies, Dehradun, Uttarakhand, India Abstract: Climate change is considered as major environmental challenge for the world. Emissions from cement manufacturing are

International Cement Review is pleased to announce the publication of the Cement Plant Environmental Handbook, 2nd Edition. This latest edition features a selection of 45 authoritative articles from leading experts, associations and cement producers from around the world, looking at best practice in ...

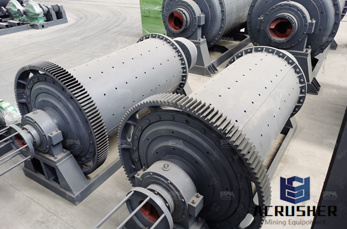

Cement Plant Operations Handbook: For Dry Process Plants. ... alite alkali analysis anhydrite ASTM ball mill belite blending burner burning zone bypass calciner calcium sulphate capacity carbon cement industry cement milling cement plant chemical classifier clinker coal combustion concrete conveyor cost crushers cyclone preheater diameter ...

Cement Mill Process Plant Handbook Keithkirstencoz . his unique handbook contains the most essential engineering formulas used in the cement manufacturing process All formulas are The book is equally valuable for the manager supervisor, chemist, and operator as it is to the cement .

Design and Detailing of LowRise Reinforced Concrete Buildings. Reinforcing Bars: Anchorages and Splices. Concrete Structures Reduce the Spread of Fire The Mercer. Register for Member Meetings. Reinforcing Basics. Concrete Benefits. Resource Materials. Markets. eLearning.

The Portland Cement Association (PCA), founded in 1916, is the premier policy, research, education, and market intelligence organization serving America''s cement manufacturers. PCA members represent 91 percent of cement production capacity with facilities in all 50 states.

Oct 10, 2015· The Cement Plant Operations Handbook, Sixth Edition 2014 by Philip A Alsop. One of the most complete books that can be found about Dry Process Cement Plant, covering the .

January 2019 This handbook has been superseded by the Cement Plant Operations Handbook 7th Edition. Fully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available. Covering some 300 pages, the cement .

Recently a close relative of mine started a hollow block and fly ash brick manufacturing unit, so I think I''m qualified to answer this question The major expense is for the land in which you are planning to set up. sure you find ...

This unique handbook contains the most essential engineering formulas used in the cement manufacturing process. All formulas are presented in both English and metric systems of units. Examples are given to familiarize the reader with the usefulness of these formulas.

handbook of cement manufacturing cement plant fan nanohvac eu handbook of cement manufacturing in kapurthala crusher for pebble cement gear box lime stone crusher for cement industry cement grinding mill separator portable cement mixer price plant layout design of cement industry cement ...

Cement Manufacturing Capacity, February 2017 "The Wall" Impact on Cement Consumption, February 2017 Stronger Sentiment, Higher Interest Rates, January 2017

More than 250,000 people work in concrete manufacturing. Over 10 percent of those workers 28,000 experienced a jobrelated injury or illness and 42 died in just one year. Potential hazards for workers in concrete manufacturing: Hazard: Exposure to cement dust can irritate eyes, nose, throat and ...

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites.

Aug 30, 2012· Cement Manufacturing Process Phase II: Proportioning, Blending Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay.

This unique handbook contains the most essential engineering formulas used in the cement manufacturing process. All formulas are presented in both English and metric systems of units. Examples are given to familiarize the reader with the usefulness of these formulas. The book can be used as a text manual for courses in cement technology, and as a reference for solving operating problems.

Quality Management System for Ready Mixed Concrete Companies Parts A and B prepared by: William C. Twitty, Jr., Part C Developed by the NRMCA P2P Steering Committee Reviewed and Approved by the NRMCA P2P Steering Committee

This Employee Handbook is not a contract of employment. It was written to help you get acquainted our Company, to give you a brief explanation of our philosophy, and to outline some of our policies and procedures. The Handbook will not answer all of your questions, but it will serve as a

Cement is seldom used on its own, but rather to bind sand and gravel together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Cement is the most widely used material in existence and is only behind water as the planet''s mostconsumed resource.

WhatsApp)

WhatsApp)