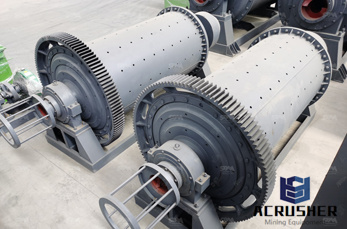

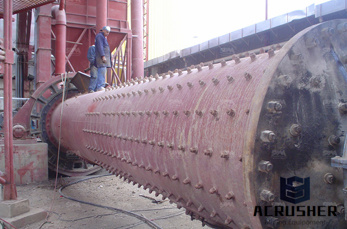

AKW Equipment + Process Design

AKW Equipment + Process Design is a mediumsized, privately owned company focused on process engineering, equipment manufacturing as well as plant construction and service.

WhatsApp)

WhatsApp)

AKW Equipment + Process Design is a mediumsized, privately owned company focused on process engineering, equipment manufacturing as well as plant construction and service.

This equipment is designed for dispersing and mixing, but not for a chemical reaction, as required in the case of silica compounds. Therefore. silica compounds require additional steps to complete the reaction between the silanolgroups of the silica .

Two hot process softener designs are illustrated in Figures 77 and 78. The former, the simplest in design and fabrication, is referred to as a "downflow" unit. The latter, which incorporates additional features, is referred to as an "upflow" unit. Many variations in design of both units exist, but the principle of operation is quite similar.

fracking regulations. Silica dust has become a major topic in the frac sand industry. To ensure your plant is meeting the required regulations an inspection of your existing systems and equipment may be necessary.

Customers in the mining – and specifically in the frac sand industry – turn to IVI to design, fabricate and install equipment, such as bucket elevators, belt conveyors and storage tanks, as well as complete industrial ventilation solutions, process air and dust collection systems. We include wearresistant materials as part of the design.

Transforming Ore Bodies Into Valuable Commodities. Whether you need process improvements to lower operational costs, convert tails into revenue, or build a new plant, we are your go to partner for extracting maximum value from your mineral processing operations across the .

SGS''s team of applied and process mineralogists have years of characterization experience. We have the equipment and expertise needed to conduct rapid, accurate silica determinations and a comprehensive quality control program. Partner with us to ensure your workplace is a .

PROCESS DESIGN OF WATER SYSTEMS (PROJECT STANDARDS AND SPECIFICATIONS) TABLE OF CONTENT SCOPE 2 ... 2 Silica content (1 French degree = 12 mg/L SiO 2 based on Table ). ... process equipment, boilers, etc.; interferes with most process uses

Frequently Asked Questions: Respirable Crystalline Silica Rule Background and Health Impacts What is crystalline silica? Crystalline silica is a common mineral found in many naturally occurring materials and used in many industrial products and at construction sites. Materials like sand, concrete, stone and mortar contain crystalline silica.

Silica Sand Pit Process Design rolvaplast. silica sand pit process design kaolin equipment suppliers. silica sand pit process design silica sand destroying process mykeralatour Sand Casting Process Defects Design 1983 A process of purifying silica sand Sand mining is a practice that is used to extract sand mainly through an open pit.

International Journal of Advanced Research in Vol. 1, Issue 1 (Apr. Jun. 2015) Mechanical Engineering Technology (IJARMET) ISSN : (Online)

Process Design for the Production of Ethylene from Ethanol Gregory Cameron University of Pennsylvania Linda Le University of Pennsylvania Julie Levine University of Pennsylvania ... This report contains a detailed description of the plant process equipment and operating conditions. Our plant is expected to be complete in 2015 and has an ...

With the development of technology, the use of silica sand is more widely,Silica Sand Mining Process Equipment according to the characteristics of quartz sand, quartz sand processing equipment, its requirements relative to other materials made relatively high, mainly due to the extensive use of quartz sand itself determined, different industries require different quality quartz sand, and how ...

We design and supply equipment to wash minerals. Our coal silica sand washing and grading plants are used across the world. View our Products. MEP Approach. We design and supply equipment to wash minerals. Our coal silica sand washing and grading plants are used across the world. View our Approach. scroll down. Our Markets.

Particle Size, Consistency and Purity Keys to Quality LUDOX ® colloidal silica products are aqueous dispersions of silica particles in the low nanometer size range that typically exhibit narrow particle size distribution. Process design and control ensure quality and consistency. Combined with excellent purity and a wide range of options, these attributes make the LUDOX ® colloidal silica ...

Silica. Silica is one of the most common hazards on a worksite, particularly in the construction, oil and gas, manufacturing, and agriculture industries. Silica dust can cause silicosis, a serious and irreversible lung disease. It can also cause lung cancer.

Last updated February 2013 Silica—Technical guide to managing exposure in the workplace Page 6 of 22 providing information, instruction, training and supervision ensuring the workplace conditions are monitored to prevent illness from carrying out work with

With years of process team knowledge, McLanan is the most experienced manufacturer of wet processing plants for frac sand production in North America. The company has a solution for all stages of the frac sand process, including crushing, screening, washing and classifying, and dewatering, as well as fines recovery, sampling and water management.

Sep 27, 2018· Gemafreie Musik von AKW Equipment + Process Design – Specialty Silica Sand Processing Plant – Tunisia Duration: 3:19. AKW Apparate Verfren 1,579 views

Process Engineering Associates, LLC (PROCESS) was contracted to (1) document the design of an existing process, (2) conduct a process design and safety review of this process, (3) develop a preliminary design for an improved process, and (4) develop a proposal to perform the detailed process design for the improved process.

What is process safety review? Process safety review is a planned and systematic brainstorming meeting for identification of potential hazards, assessment of risk and reviewing the readiness and effectiveness of risk control measures to ensure safety for personnel and equipment systems in a process plant.. Objective of safety review. The objective of safety reviews is to ensure the design .

Process Solutions. Metallurgical Testing Process Design. Equipment Design Selection. Gravity Separation. Centrifugal Jig Technology. Electrostatic Separation. Magnetic Separation. Shaking Tables, Knudsen Bowl. Process Audits Optimisation. New Products from RD. Plant Design. World''s Largest Mineral Sands Plant Design. Innovative Iron ...

EGM is a leading producer of valueadded process and chemical feed systems for a wide range of industries and applications. Our equipment design and manufacturing expertise is backed with years of specialty chemical sales, service and application development experience.

Jul 06, 2017· AKW Equipment + Process Design – Specialty Silica Sand Processing Plant – Tunisia ... Superior Silica Sands 2,471 views. 9:53. Invisible Drywall Repair WITH NO PLASTER!

WhatsApp)

WhatsApp)