RoM BALL MILLS A COMPARISON WITH AG/SAG MILLING

II314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of Cape Town, Rondebosch, 7700, South Africa ...

WhatsApp)

WhatsApp)

II314 RoM Ball mills – a comparison with AG/SAG Milling Aubrey N. Mainza1 and Malcolm S. Powell 1 1Mineral Processing Research Unit, University of Cape Town, Rondebosch, 7700, South Africa ...

4 High ball charge SAG mill or ROM Ball mill (15 to 25% ball charge) Low competency ore Hidden Valley, Nzema, Sepon, UG2 ores (South Africa), Yanacocha 5 Low ball charge, high speed SAG mill (4% ball charge, 90% Nc) A cross between AG and SAG for average competency, abrasive ores. Typically operated in RSA on Witwatersrand Gold Ore Driefontein ...

A SAG mill is generally used as a primary or first stage grinding solution. Attrition between grinding balls and ore particles causes grinding of finer particles. SAG mills are characterized by their large diameter and short length as compared to ball mills. SAG mills are primarily used at gold, copper and platinum mines with applications also ...

mills in the older plants that had many mills in parallel. In fact this is generally still the case in the multistream plants, where mill liner design and selection is only tackled on a cost consumables basis. However, the gains to be had through good liner design and selection are just as great as on the large SAG mills.

stage ball mills, rod mills or AG/SAG mills when calculating power according to the Bond Third Theory method. Rod mill and AG/SAG mill products are similar and tend to be not as steep as a slope when plotted on loglog paper. This is because the particle size distribution (PSD), these mills

SAG milling extends itself to many applications due to the range of mill sizes available. They can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill and some or all of the work done by a ball mill. SAG mills are also an optimum solution for wet grinding since crushing and screening in these ...

SAG Mill Grinding Media Read reviews ... Our steel forged grinding balls in the diameter range of "6" are classified as SAG balls and are primarily used in SAG mill operations. ... the least wear rate among 3 competitor products by showing the lowest consumption rates of /t and kg/t for ball and SAG mills respectively. Surface and ...

AG/SAG mills can accomplish the same size reduction work as two or three stages of crushing and screening, a rod mill, and some or all of the work of a ball mill. Because of the range of mill sizes available, AG/SAG milling can often be accomplished with fewer lines than in a conventional rod mill/ball mill circuit. A diagram of types of AG/SAG ...

The SAG Mill is a machine added by Ender uses Redstone Flux (RF) to grind (or mill) items into their crushed variants, like Ores into SAG Mill has four output slots; recipes can have 14 different outputs, with different chances of obtaining those outputs. Dark Steel Balls or Flint can be put in the processing slot (right side of the GUI, left of the process bar) to increase ...

Oct 12, 2017· SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating drum of SAG mill which is filled with balls partially.

• Single stage crush/single stage SAG mills and two stage crush/ball mill circuits are typically selected for low throughput plants (<50 t/h) where personnel costs are a large component of costs. • SAB circuits are typically selected for plants of to 2 Mt/a.

Mill Power Draw Models. The mill power draw models are used to predict how much power will be consumed by a particular type of mill, mill geometry and set of mill operating conditions. This power is transferred to the ore and used to predict the throughput when combined with the specific energy consumption models.

Aug 11, 2015· Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and timely replacement of the parts should be done.

Jan 08, 2016· In this training module, we''ll cover the workings of a semiautogenous grinding mill, or SAG mill, that''s designed to be the first stage of a grinding circuit. Ore that''s crushed in a primary ...

Mill Critical Speed Determination. The "Critical Speed" for a grinding mill is defined as the rotational speed where centrifugal forces equal gravitational forces at the mill shell''s inside surface. This is the rotational speed where balls will not fall away from the mill''s shell.

Dec 21, 2016· 2 parallel SAG Mills each feeding 2 parallel Ball Mills (4 total). Around 50,000 TPD total grinding circuit capacity.

Oct 22, 2012· Before the Esperanza order, FL''s largest SAG mill measured 38'' and its ball mills, 26''. To the average person, the difference between a 38'' and a 40'' SAG . Autogenous mills, semiautogenous mills and ball mills for wet . SAG and ball mill for gold ore grinding. One of three SAG mills with m diameter and 2 x 4000 kW drive power.

We offer the most reliable choice for all kinds of Ball Mills, Rod Mills, Pebble Mills, SAG Mills, Mine Hoists, Crushers, Synchronous Motors, DC Motors, Flotation, Mixers, Pumps, Diesel Generators, Natural Gas Generators and all the Mining Equipment you require.

Increase SAG mill and ball mill tonnage with better efficiency. The GrindingExpert™ solution will automatically adjust feed rate, mill speed and water addition to reduce upsets, eliminate grindouts and increase tonnage in SAG / ball mills. Our solution utilizes cutting edge smart sensors to analyze incoming ore properties and measure the ...

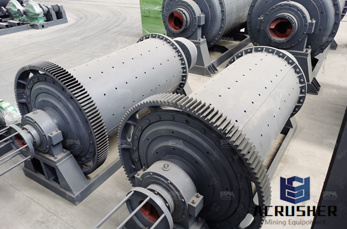

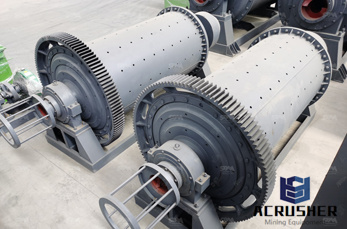

All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

equipment. Outotec''s grinding mill range includes semiautogenous (SAG) mills, autogenous (AG) mills, ball mills, pebble mills, scrubbers, rod mills, High Intensity Grinding (HIG) mills and High Pressure Grinding Rolls (HPGR). Outotec specializes in providing mills which are The key to .

Morrell SMC SAG ball mill Model. This is a SAG or AG mill plus ball mill model that estimates the specific energy consumption (E SAG) using the equations of Morrell (2004). Testwork Required. The SMC™ test, stored in the "DWT" testwork table (SMC is a Drop Weight Test). Bond ball mill work index.

is home to a collection of both free and subscriptionbased calculation tools to aid metallurgical process engineers perform comminution calculations. Grinding circuit design tools, including for SAG millball mill circuits, and geometallurgy energy models are available to subscribers.

offers 1,291 sag mill products. About 12% of these are mine mill, 10% are casting, and 1% are grinding equipment. A wide variety of sag mill options are available to you, such as ball mill, raymond mill.

WhatsApp)

WhatsApp)