What ways are there to produce ceramic balls?

What ways are there to produce ceramic balls? ... (Al2O3) powder and I want to decrease its particle size down to 1520 micron with ball milling. I have a few questions:

WhatsApp)

WhatsApp)

What ways are there to produce ceramic balls? ... (Al2O3) powder and I want to decrease its particle size down to 1520 micron with ball milling. I have a few questions:

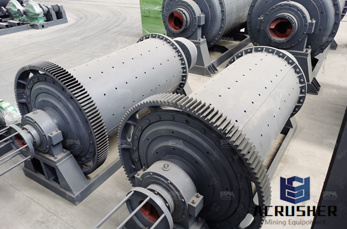

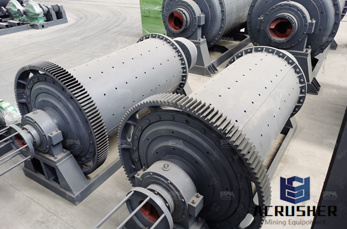

Diagram Of Ball Mill Machine Pdf,, a typical hammer mill diagram; of a well label universal milling machine a typicalelectrical block diagram ball millquarry attrition mill diagram. Design Method of Ball Mill by Sumitomo Chemical . A ball mill is one kind of grinding machine, and it is a device in which media balls and solid materials (the ...

· ceramic or dry ball mill 3. overflow Trunnion Overflow Discharge charge trunnion liner ball mill liner, there are. 4,5/5(2,7K) ... Schematic diagram of coneend of a wet system ball. flow diagram ball mill dwgXinhai Mining After the usual type of trunnion bearing the mill.

ceramic tiles used in mills suppliers in south africa; ceramic raw material supplier in saudi; ceramic tiles process diagram; ceramic sand stainless steel plant; ceramic ball millceramic ball mill manufacturerceramic ball; ceramic aquatek pantip; ceramic glazing making equipments; ceramic sand processing unit; ceramic company overview ppt ...

Grinding in ball mills is an important technological process applied to reduce the ... Ceramic balls with regular density are usually porcelain balls and the high ... [23] by a diagram shown in Fig. 3. The left column of the figure shows the size distribution of the feed. The application

CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or rubber linings for wet or dry grinding, for continuous or batch type operation, in sizes from 15″ x 21″ to 8′ x 12′. High density ceramic linings of uniform hardness male possible thinner linings and greater and more effective grinding volume. Mills are shipped ...

small ball grind ball mill for sale Ball Mills The Ceramic Shop. We ship world wide and offer deep discounts and sales! . ball mill, ball mills, ball mill jar, ball mill jars, glaze grinding . mix as ...

Ceramic grinding media are also suited for use in processes where mixing and dispersing effects play an important role. In the majority of these grinding processes, steatite and alumina are the most common ceramic materials used for grinding balls and linings. CeramTec generally manufactures its grinding balls and linings with steatite.

offers 3,753 ceramic glazing machine products. About 9% of these are tile making machinery, 9% are ceramics, and 8% are mine mill. A wide variety of ceramic glazing machine options are available to you, such as colored steel, ceramic, and steel.

Fine grinding or milling reduces the particle size down to as low as micrometer in diameter. Ball mills are the most commonly used piece of equipment for milling. (3) Filter Press During the process to make clay and ceramic slurries used for the manufacture of dinnerware, insulators, china etc,

Ceramic Tile Manufacturing Process Flow Chart. FENIX CERAMIC. Fenix ceramic is the best manufacturer of tiles . PRODUCTION PROCESS FLOW CHART . The vitrification process enables the tile to have various mechanical and .

Wet FGD System Overview and Operation Ray Gansley WPCA Wet FGD Seminar Power Gen International December 1, 2008. Agenda ... BALL MILL TO BALL MILL FROM MW TANK GYPSUM REAGENT PREPARATION ABSORBER DEWATERING Process Flow Diagram WPCA Wet FGD Seminar December 1, 2008. Agenda • Introduction • Major Process Equipment • Balance of Plant ...

Jan 29, 2013· ceramic ball mill diagram . an efficient grinding tool which is capable of grinding various types of material into fine powder. 2. . make ceramic glaze, .Ball Mill .

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Diagram of ball mill and interior cut away [image: (13572)] Ball Mill Design Parameters. Size rated as diameter x length. Feed System. One hopper feed; Diameter 40 – 100 cm at 30° to 60° ... Pebbles and ceramic media ...

The IsaMill is a stirredmedium grinding mill, in which the grinding medium and the ore being ground are stirred rather than being subjected to the tumbling action of older highthroughput mills (such as ball mills and rod mills). Stirred mills often consist of stirrers mounted on a rotating shaft located along the central axis of the mill.

Grinding in Ball Mills Modeling and Process Control. · Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics. Typical examples are the various ores, minerals, limestone, etc.

The attritionmilling technique for producing high surfacearea materials has been patented by the Bureau. Mathematical Model of the Attrition Mill. As an offshoot of the ceramic milling studies, an investigation was made to develop a mathematical model of the attrition grinder.

schematic diagrams for dry ball milling circuits – Coal . Roll crusher; Gyratory cone crusher; . The wet ball mill load in, Schematic diagram of the grinding circuits system Mill .

Dec 05, 2012· Overflow Type Ball Mill/Grate Ball Mill/Ceramic Ball Mill/Rubber .. Shanghai MG China supplier of Ball Mill,Ceramic Ball Mill,Cement Mill,Raw . cylinder liner,big gear ring .It The overflow ball mill has relatively simple structure . »More detailed

Mounting Diagrams. Rough In mounting diagrams for informational purposes. Open PDF. Wholesale and Large orders. For pricing and availability of large quantity and custom orders. Contact. Porcelain Ball Mill Jars. Ball Mill Jars are made of high quality, high fired Porcelain, these jars are designed to be used on any standard ball mill roller.

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are used as media, including ceramic balls, flint pebbles and stainless steel balls.

Spray drying is a method of producing a free flowing, uniform, granulated powder, which is the ideal feedstock for a variety of pressing processes, such as uniaxial pressing and wet and dry–bag isostatic pressing. The raw material blend is firstly milled in a ball mill in a solvent, such as water, using ceramic .

Ball Mill Instruction Manual (PDF) Ball Mill Diagram Sheet (PDF) The software to view and print Adobe Acrobat (PDF) is available for free from the Adobe . Ball Milling – Free Download (pdf,doc,xls,rtf,ppt,pps documents)

WhatsApp)

WhatsApp)