cement plant process flow diagram ppt YouTube

Jun 05, 2018· Cement Mill Process Flow Chart mill process flow chart Cement Manufacturing ... which can finish all the steps of raw mill flow diagram for cement plant .

WhatsApp)

WhatsApp)

Jun 05, 2018· Cement Mill Process Flow Chart mill process flow chart Cement Manufacturing ... which can finish all the steps of raw mill flow diagram for cement plant .

Aug 30, 2012· Generally cement plants are fixed where the quarry of limestone is near bye. This saves the extra fuel cost and makes cement somehow economical. Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing.

Advantages of Pearson Water Heating Systems: Simple, efficient, rugged, reliable, and designed specifically for concrete plants; Dozens of configurations can be custom built for your specific water heating demands and plant layout: seven different burner sizes, approved burner operates on #2 fuel oil, natural gas, propane or combination of gas and oil, and high volume multiburner units ...

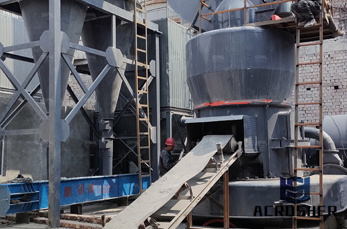

Thermodynamic Performance Analysis of a Raw Mill System in, A schematic diagram of the raw mill system in a cement plant is illustrated in Fig 1 In this process, raw materials, such as CaCO 2, SiO 2, Al 2 O 3, Fe 2 O 3, MgO, K 2 O, SO 3, and Na 2 O at the reference temperature and pressure enter the raw mill system to produce farine...

The Industry Has Spoken. McNeilus FLEX Controls™ Awarded Two Industry Awards McNeilus was recently honored with two industry awards for their FLEX Controls™ system equipped on McNeilus concrete mixers. FLEX Controls are now a "Top 100 New Products of 2017," recognized by Construction Equipment magazine and a "2018 Most Innovative Product (MIP)" at World of [.]

A concrete plant, also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form concrete. Some of these inputs include water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and cement.

CONCRETE BATCH PLANTS FOR THE WORLD''S TOUGHEST JOBS. CONECO® mobile and stationary concrete batch plants are built to maximize your productivity, the quality of your mix, and your return on investment. Choose from among the industry''s widest range of central mix batch plant and transit mix batch plant models and capabilities.

Sep 17, 2015· 15 Cement Storage Silo The cement storage silo is used for storing the finished product – cement. 16 Packing and Dispatch The cement is packed with the help of a rotary packer and finally dispatched to the market. 15. 17 Central Control Room It is the nerve center of the cement plant since all equipment is controlled from this place.

Alternative Fuel Use in Cement Manufacturing 6 Emissions from cement production More than 50% of the total CO2 from cement production results from the chemical reaction that converts limestone into clinker, the active ingredient in cement.

May 11, 2013· Cement manufacturing process components of a cement plant from quarry to kiln to cement mill. ... Cement Manufacturing Process Simplified Flow Chart. Posted by Johnny. May 11, 2013. ... Cement Manufacturing Process Simplified Flow Chart

The Vista Cement Plant project aims to construct a new cement production plant with two production lines, each with a production capacity of 3,500 tonnes of clinker per day. The total production capacity of the plant for different kinds of cement is planned to be 10,000 tonnes. This plant will especially

Toulouse, France based company which is specialized in the production and marketing of all types of precast concrete elements has received its new Mix Master30 onsite concrete mixing plant recently. ELKON''s Mix Master30 is an ultra mobile and towable concrete batching plant thanks to its wheels.

MPParts has the fastest, friendliest service in the Concrete and Heavy Truck Industries. We are family owned and operated, whether you need Concrete Mixer Parts or an entire Concrete Batch Plant, MPParts has you covered. With over 65 years experience in the industry, we understand the importance of fast, accurate service to keep your concrete up and running.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Volume 3, Issue 5, November 2013 385 Abstract— formalized by French and British engineers in the 18th This paper analyzes an existing processing management system in a cement factory in India. During the last two decades (80''s and 90''s), major technological advancements took place in design of cement plant equipment/systems. The

Mar 09, 2017· concrete batching plant control system is equipped with precise batching machine equipment, you can control a number of independent batching lines, each line can be set according to user requirements, said the focus. In addition to the sensor, the...

Certified by the Manufacturer to comply with the concrete plant mixer test procedures for measuring the withinbatch uniformity of the plant mix concrete performance evaluation test of the plant mixer manufacturers division. Concrete Plant Manufacturers Bureau. ... Concrete Batching Plant .

Dec 17, 2012· Through this analysis we have determined the Top 20 global cement companies and those close behind. We comment on their place in the cement industry in different world regions. The global cement industry is a good indicator of the growth and progress of a country as cement consumption is closely linked to percapita income.

A concrete plant, also known as a batch plant or batching plant, is a device that combines various ingredients to form concrete. Some of these inputs include sand, water, aggregate (rocks, gravel, etc.), fly ash, potash, and cement. There are two ...

Cement plant laboratories check each step in the manufacture of portland cement by frequent chemical and physical tests. The labs also analyze and test the finished product to ensure that it complies with all industry specifications. The most common way to manufacture portland cement is through a dry method.

Energy and Cost Analysis of Cement Production Using the ... The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. En ... Material and energy flow diagram for dry process manufacturing of cement. Figure 2. Material and energy flow diagram for wet process

Cement Plant Process Diagram, Find Complete Details about Cement Plant Process Diagram,Cement Plant Process Diagram,Cement Production Line,Cement Production Line Layout from Cement Making Machinery Supplier or ManufacturerZhengzhou Huanqiu Heavy Industries Ltd.

States. The balance of domestic cement production is primarily masonry cement. Both of these materials are produced in portland cement manufacturing plants. A diagram of the process, which encompasses production of both portland and masonry cement, is shown in Figure As shown

batched or prepared at a building construction site. Figure is a generalized process diagram for concrete batching. The raw materials can be delivered to a plant by rail, truck or barge. The cement is transferred to elevated storage silos pneumatically or by bucket elevator. The sand and coarse

WhatsApp)

WhatsApp)